TRU Group Lithium Best Practice - Press Release

New CIM NI 43-101 lithium reserve estimation guideline falls short - TRU Group propose best practice corrections at Las Vegas lithium conference

Update Jan 2020 - ISSUE PERSISTS - CIM Best Practice Guidelines for Resource Reserve Estimation of Lithium Brines

TRU Group Inc, Tucson AZ, USA Toronto ON release November 26, 2012 - Lithium consultants TRU Group Inc says that the “Best Practice Guidelines” for Lithium Brine reserve estimation are deficient and could lead to substantial overestimation of lithium resources, if applied. The guidelines recommend a manner for estimating brine resources and reserves that would include both potential brine producing aquifers with extractable lithium along with associated low permeability sediments, which may contain brine that is not extractable by economic means. Such sediments should be excluded from any resource estimate.

The “CIM Best Practice Guidelines for Resource and Reserve Estimation for Lithium Brines” was published November 1, 2012. Dr Kunasz will present his review of brine guidelines and make recommendations for lithium resource definition at the IM Lithium Supply & Markets conference January 29, 2013.

Ihor Kunasz Ph.D (Geol), P.Geol, is well known as the geologist who developed the original reserve model for the very first lithium brine deposit at Silver Peak, Nevada and defined the lithium resources for the Salar de Atacama deposit from whence sixty per cent of the world’s lithium is currently produced. He developed the original resource and production feasibility study for the Chemetall-SCL - CORFO (Chilean Development Corporation) Joint venture. His full presentation "Lithium reserve estimation Best Practice Pitfalls - common errors found in NI 43-101 reports" will be available on the TRU website late January 2013.

TRU Group Inc is technical engineering consultants with a strong capability in lithium. The firm is a world leader in lithium resource evaluation & exploitation, lithium extraction processing technologies and lithium chemical engineering. TRU has evaluated and modeled most of the known existing lithium properties and advised a number of players on a wide variety of lithium resource, engineering, process, business and investment issues.

The TRU website is trugroup.com and the author Kunasz presentation "BRINES RESOURCES AND RESERVES" can be viewed below.

Contact: Edward R. Anderson B.Sc.(Hons)., Dpl.(Marketing Research)., MBA., FCIArb President & CEO TRU Group Inc Website: trugroup.com Email anderson@trugroup.com Tucson 520-575-0674 Toronto 416-935-1754 Cell 1-520-229-7836

BRINES RESOURCES AND RESERVES

Analysis of and Practical Recommendations for CIM’s Publication “Best Practices for Resource and Reserve Estimation for Lithium Brines”

By

Ihor A. Kunasz Ph.D (Geology)

Registered Member No 1804820

Society for Mining, Metallurgy and Exploration

ABSTRACT

The high lithium demand forecasted for some high tech applications and batteries for electric and hybrid-electric vehicles, in particular, has sparked increased exploration for lithium, particularly for lithium-and-potassium bearing brine deposits. Resource reporting for brines has generally followed the Canadian Institute of Mining NI 43-101 guidelines formulated for hard rock deposits (metal and industrial minerals). While a number of the requirements can be appropriately applied to brines, brines are fluids and require a specific analysis leading to a distinct set of reporting requirements. Brines cannot be considered industrial minerals because the various elements occur as ions in a dynamic fluid, rather than being chemically bonded in a solid. Although chemicals are produced from brines, brines have no relation to industrial mineral deposits. This paper proposes to analyze the recently released (November 1, 2012) document “CIM Best Practice Guidelines for Resource and Reserve Estimation for Lithium Brines”, in light of the practical knowledge available from existing brine operations and recommends modifications to the guidelines, which if applied in their present format may result in overstating resources and reserves and potentially mislead investors.

Introduction

The Best Practice document is a generally descriptive document, which does not fully address the methodology for brine resource or reserve definition. The lithium and other elements are contained in a fluid, the identification of which should be the principal focus of a brine exploration program. The fundamental requirement in defining lithium brine resources and reserves in a salar is the identification and definition of those formations - the aquifers - that will yield brine in a usable quantity to a well, because brines can only be extracted by pumping wells. Fine-grained sediments will never, as required in the summary table (page 9), have “reasonable prospects of economic extraction”, and therefore need not be tested. However, the Guidelines recommend the collection of solid samples and a high core recovery

Analysis

While lithium-bearing fluids are present in the pores of various salar sediments, only those formations that will release brine when a pressure differential is applied (by a pumping well) should be investigated. In the CIM Guidelines, the term “aquifer” is used throughout the document, but no formal definition is provided. An aquifer is:

- A water (or brine)-bearing layer of rock, or of unconsolidated sediments, that will yield a usable quantity of water (or brine) to a well.

The document, instead, discusses “salar porosity and permeability and transmissivity on resource volume,” (page 2), “the pores of the salar matrix “and “salar brines are contained within a matrix” (page 4). This terminology is incorrectly applied to include all sediments are included, whereas such terms can only be applied to those specific formations – the aquifers - that can yield brine upon pumping; they should not encompass the whole salar matrix which includes fine-grained sediments that will not release brine upon pumping and, therefore, cannot be included in a resource determination. The mechanism for “extracting” brine is a well, which is typically constructed using techniques similar to a water well. Pumping is the only method for brine recovery (sometimes, trenching in the upper portion of some mature salars). For this reason, an exploration program must first and foremost identify those formations that can produce brine and have reasonable prospects of economic extraction.

Resource vs. Reserve

Once aquifers have been identified and their areal distribution established, a preliminary resource can be calculated using the following parameters:

Aquifer areal extent

Flow potential (to be later confirmed by pumping tests)

Element concentration

Hydraulic parameters.

Refinement of resources (measured, indicated…) should be based, as pointed out in the guidelines, on the density of the test drilling as well as concentration grade cutoff and flow characteristics. Low flows and low concentrations should be categorized as indicated, while higher flow rates and high element concentration would be a measured resource. In no event, should fine-grained sediments be included. Reserves should be defined by a tighter drill hole pattern to better define the area, thickness, grain size (important in designing the gravel pack for production wells) and specific yield of the formation.

The continuity of the aquifer(s) is also important because it will predict long-term brine availability. As a production well impacts adjoining wells, the well field design relies on the optimum interference between wells. If the interference pattern is areally extensive, this will confirm aquifer continuity and will eliminate the need for more closely spaced exploration wells. Ultimately, this information will dictate the number of wells required to supply brine for a given chemical plant production capacity. In mature salars, numerical methods can be used to predict the drawdown of the brine under different pumping scenarios and to define the life of the reserves. The Guidelines incorrectly recommend, “Resources may be defined as the product of three parameters”:

1. Aquifer Geometry

2. Specific Yield

3. Element Concentration

Fine-grained sediments can be, indeed, characterized by area, specific yield and element concentration. However, since those sediments will never yield brine, the calculation of a resource is not only irrelevant, but will generate an erroneously inflated resource number. In practice, the geologist logging the wells can readily identify permeable and impermeable sediments visually using published information (Heath, 1984, p.13)). This is not explicit in the Guidelines. The part of the porosity that may be drained under gravity is known as the specific yield or, sometimes, drainable porosity. To apply this parameter for resource calculation implies that:

An aquifer(s) has been intercepted during exploration and;

Brine will be available during pumping.

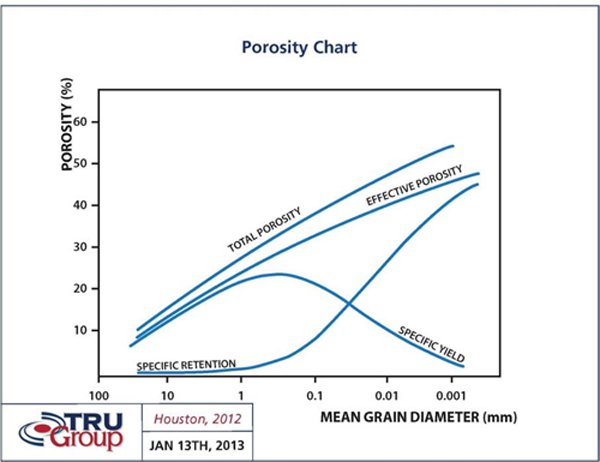

The above diagram (Houston et al., 2012) illustrates the relationship between various parameters. Although clays and silts have a high porosity, they have a very low to negligible specific yield and high specific retention. Therefore, to recommend core drilling and sample collection of fine-grained sediments for porosity and permeability testing is unnecessary. Unfortunately, in some technical reports, resources have been calculated for all sediments in the salar. A review of geologic logs, however, indicates that clays and silty clays make up the bulk of the basin sediments. The report includes extensive laboratory-tested specific yields, which were subsequently used to generate block models using kriging techniques. This is faulty since fine-grained sediments, while containing large amounts of brines in their pores will never yield brine upon pumping. The reported resources are clearly overstated and invalid. Kriging techniques, if used, can only be applied to identified, known aquifers. The Guidelines should recommend that detailed parameters be obtained only from identified aquifers, thus avoiding substantial costs in laboratory testing of fine-grained sediments and erroneously inflated lithium resources.

Brine Exploration Methodology

The most efficient and proven exploration method aquifer identification is the Dual Wall Reverse Circulation Drill- DWRR (Strauss, 1989). Designed by two Canadian drillers, the DWRR technology allows not only for the precise identification and recovery of the various sediments but also the collection of brine samples from producing zones by airlifting and identifying high and low flow intervals. Since the drill hole is cut with a close tolerance, excellent brine quality samples can be obtained from unconsolidated aquifers. At the Foote Mineral Company (Rockwood) Silver Peak Lithium Brine Operation in Nevada, hundreds of DWRR exploration holes and over 100 production wells have been drilled since the start of operations. The data provided not only accurate geological samples but also important hydrological information and resulted in the determination of an empirical relation between the flows recorded during DWRR drilling and expected production well flows (Bell, 1984). Additionally, practical experience indicates that sample contamination mentioned in the Guidelines is not an issue.

It is remarkable that, in several exploration programs, which used reverse circulation drilling, no flow data have been reported. Therefore, in the first phase of exploration, the drilling procedures should focus on the identification of aquifers. While the DWRR drilling technology is well known for hard rock exploration, it would appear that the committee members were not familiar with the importance of DWRR drilling as an exploration tool in salars. However, it should be incorporated in the CIM Best Practice Guidelines. The document states that Qualified Persons (QP) should have “relevant experience in salar geology and brine processing”. The requirement does not include experience in exploration of terriginous salars, the identification and testing of brine aquifers and the design of production wells. Since there is only one such operation – Silver Peak – Nevada, it suggests that few have the overall expertise in recommending the appropriate exploration methodology, production of brine and resource calculation from terriginous salars.

Recommendations

As stated in the introduction “the practices are likely to evolve and improve with time”. There is practical experience in continental brines (Silver Peak, NV with over 40 years of production records, and Olaroz’s detailed evaluation by Houston) to recommend practical guidelines for the determination of brine resources. A brine deposit can only be qualified by the ability of aquifers to deliver brine to a pumping well, which satisfies the CIM requirement “to meet the definition of reasonable prospects of economic extraction”. Therefore, the first and foremost responsibility of the QP is to design a basic exploration

Therefore, the first and foremost responsibility of the QP is to design a basic exploration program to identify the aquifers, which will eventually support production wells. The most practical and efficient exploration method is the Dual Wall Reverse Circulation Drill – DWRR (Strauss, 1989). An exploration program should include the following steps:

- Secure proper permits and qualified contractor(s)

- Conduct shallow surface geochemistry to assess distribution of lithium and other elements over the salar

- Analyze the geological and structural elements of the salar

- Conduct appropriate geophysical tests to define the geometry of the basin (basin are often asymmetric)

- Drill to identify aquifers by DWRR drilling (using the surface geochemical and geophysical data)

- Record the preliminary flow rates from the DWRR drilling

- Collect DWRR brine samples for chemical analysis

- Collect sediments for lithology definition and aquifer grain size analysis (important in designing production well gravel packs)

- Define the areal distribution of the aquifers

CONCLUSION

The Guidelines have attempted to modify the requirements for Metals and Industrial Minerals, yet have retained much of their sampling methodology (core drilling, etc.). However, since the purpose of the document is to focus on lithium brines, there is great need to improve the guidelines to truly reflect the most important requirement: the availability of sufficient brine and the identification and characterization of permeable formations, which have “reasonable prospects of economic extraction”. Hopefully, this paper will provide appropriate and practical guidelines for brine exploration to prospective exploration personnel. We also hope this analysis has offered positive recommendations for improving the existing Best Practice Guidelines.

Acknowledgment

The author is grateful for the expertise and suggestions of E. Joel Christophersen, B.S. Geology, MBA, Operations Manager (Former), Silver Peak, Nevada Brine Field.

Ihor Kunasz

Registered Member No 1804820 (SC)

Society for Mining, Metallurgy and Exploration January 25, 2013

1 Ihor A. Kunasz is a former VP at Foote Minerals. He developed the original reserve model for the very first lithium brine deposit at Silver Peak, NV and defined the lithium resources for the Salar de Atacama deposit from whence sixty per cent of the world’s lithium is currently produced. He also developed the original resource & production feasibility study for the Chemetall-SCL-CORFO (Chilean Development Corp) JV. He was also He was also GM in South America for the largest US drilling company. Over thirty years of lithium experience.

References

- Bell. R., 1984, Advantages and Limitations of Dual-Wall reverse circulation Rotary Drilling for Ground water in Unconsolidated Sediments, Professional Engineering degree, University of Wisconsin-Madison (unpublished)

- Best Practice Guidelines for Resource and Reserve Estimation for Lithium Brines, CIM, 2012.

- Heath, R., G., 1984, Basic Ground water Hydrology, U.S. Geological Survey Paper 2220

- Houston, J., Butcher, A., Ehren, P., Evans, K., Godfrey. L., 2012, The Evaluation of Brine Prospects and the Requirement for Modifications to Filing Standards, Economic Geology, 106, 1225-1239

- Kunasz, I.A., 1970, Geology and Geochemistry of the Lithium Deposit in Clayton Valley, Esmeralda county, Nevada, Ph.D. Thesis, The Pennsylvania state University, State College, Pa.

- Strauss, F., Story, S. L., Melhorn, N., 1989, Applications of Dual-Wall Reverse Circulation Drilling in Ground Water Monitoring and Exploration, GWMR.

TRU Group Inc based in Toronto, Canada and Tucson, USA are industrial management and engineering consultants with a strong capability in lithium project development. The firm is a world leader in resource evaluation, salar exploitation, brine & mineral lithium extraction and processing technologies - those in use, prospective, and leading edge. TRU Group Lithium Team has evaluated and modeled most of the known existing lithium properties and advised a number of players on a wide variety of lithium resource, engineering, process, business and investment issues.

Concepts for New CIM NI 43-101 lithium reserve estimation guideline falls short - - TRU Group will propose best practice corrections at the lithium conference in Las Vegas: CIM Best Practice Guidelines for Resource and Reserve Estimation for Lithium Brines, APPLICABILITY OF NI 43-101 TO BRINE PROJECTS National Instrument 43-101 – Standards of Disclosure for Mineral Projects (NI 43-101), Consideration as Industrial Minerals, Best Practices Guidelines for Reporting Mineral Resources and Mineral Reserves for Industrial Minerals as issued by the CIM. RESOURCE/RESERVE ISSUES SPECIFIC TO SALARS, Brine Hydrology and Water Balance, Porosity, Permeability, Hydraulic Conductivity, Transmissivity, Anisotropy and Resistance, ESTIMATION OF RESOURCES AND RESERVES, Acknowledgments The author is grateful for the comments and reviews provided by John Houston, members of the CIM Mineral Resource and Mineral Reserve Committee and the CIM Best Practices Committee, and the contribution of the technical staff of the Ontario Securities Commission in development of these Best Practices Guidelines. Don H. Hains, P. Geo Donald Hains 2020 revised